Management of machinery equipment

with RFID

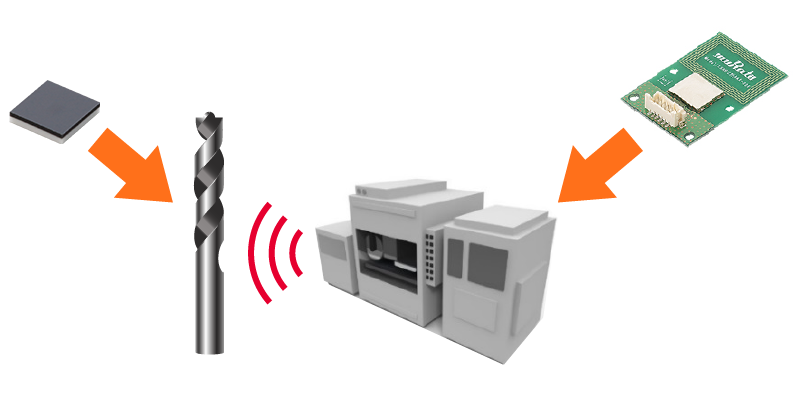

With RFID technology Murata can reveal hidden costs in production.

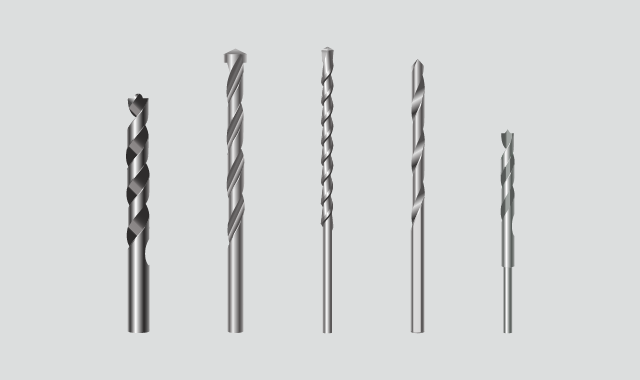

Production machinery has a variety of equipment that requires replacement based on specified life time.

Stock management of this equipment that is waiting for replacement parts, in case of stock shortage, can be a hidden cost for production.

In addition to solving above problem in user side, manufacturers of those machinery equipment can also utilize RFID to communicate information such as product specification and EOL notification to customers, which can add more value on their products and service.

* The pocket type reader shown in this page, Blueberry UHF MS4 is the product from Tertium Technology.

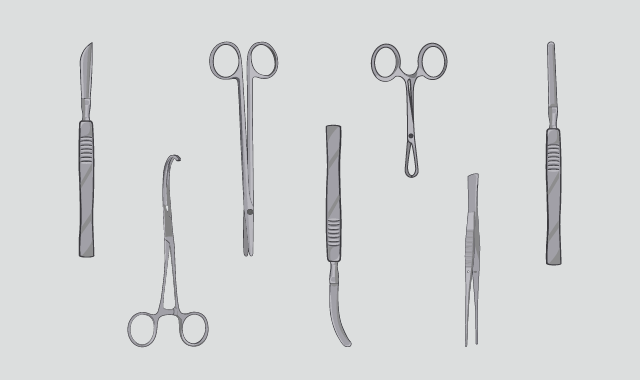

Difficulties in machinery consumable management

Both manufacturers and users spend time and manpower on management of product information.

Please flick and have a look.![[Manufacturer] Communication such as EOL (End of Life) notification and alternative product information notification to users. Loss of opportunity on the manufacturer side due to use beyond the equipment or tool's life. It is necessary to deal with defects. [User] Malfunction due to use beyond the equipment or tool's life. It takes time to manage product life. It becomes difficult to read with QR codes and bar codes due to dirt from water and oil.](../../../asset/solution/img/img_ex_tools-equipment03.png)

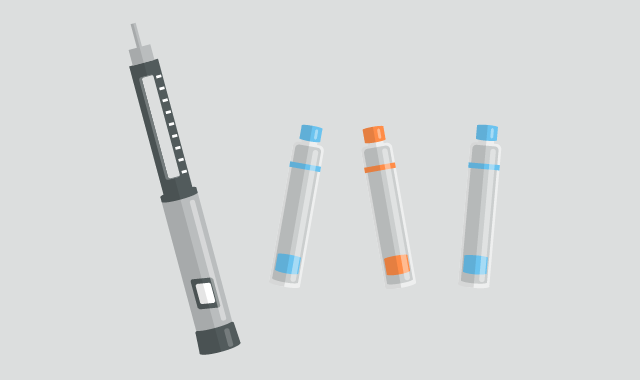

Advantages of RFID

Centralized management of product information through a database

can reduce effort on for both manufacturers and users.

![[Manufacturer] Check usage history when trouble occurs. Necessary product information can be added, so it is possible to support replacement by purchase in line with life and simplify communication with users. [User] Easily manage inventory,by attaching a small tag to the product to enable reading even if it gets dirty from moisture or oil. When replacement is required, the product name can be confirmed and ordered smoothly by reading the RFID.](../../../asset/solution/img/img_ex_tools-equipment04.png)

Why RFID

- RFID tag can be read even when covered by water or oil.

- Possible to write product information, inspection history of life management, etc.

- Password lock function prevents false modification of data.

Why Murata

-

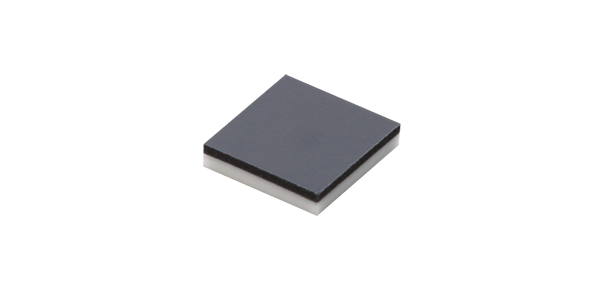

- Small and robust.

-

- Can be attached to thin and small products.

-

- Ceramic packaged tag is durable in harsh environments.

-

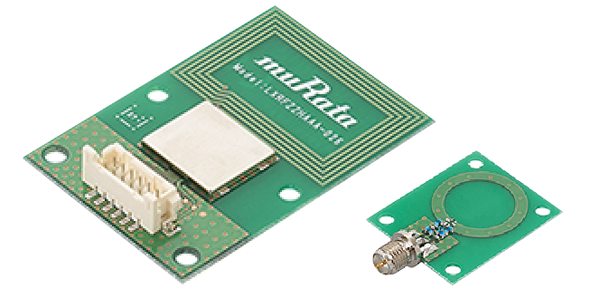

- Murata can support reader writer integration and antenna design as well as RFID tag.

Reading method

-

- small tags attached to products can be read/written with a portable reader writer

-

- reader writer antenna built into facility can identify tools with small tags when installed

How to attach

- Adhesive

- Double sided tape

- Injection molding, etc.

Read range (Reference)

- Reading in near field (Contact ~20mm)*

* Read range is subject to change upon the evaluated environment. We offer suggestions and support based on your usage.

For customers looking for RFID tag/reader-writer.

Murata also offers hardwares from the lineup of RFID tag and reader-writer. Please find the detail in the product page.