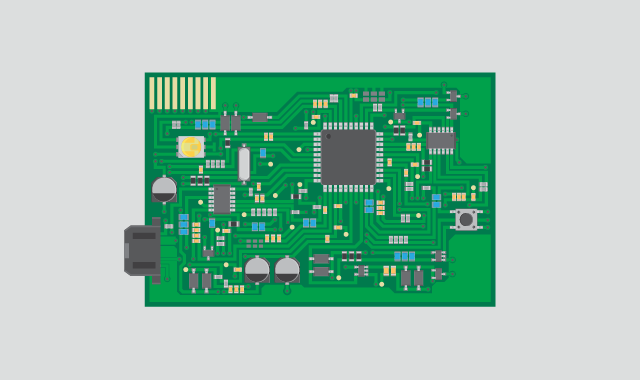

PCB management with RFID

With RFID technology Murata can support the realization of smart factories.

The first step for a smart factory is the management of production records for each product.

Generally labels with QR codes or Barcodes are the typical methods for tracking production records of PCB.

However, label printing and the adjustment of the reading camera consumes your time and Manpower.

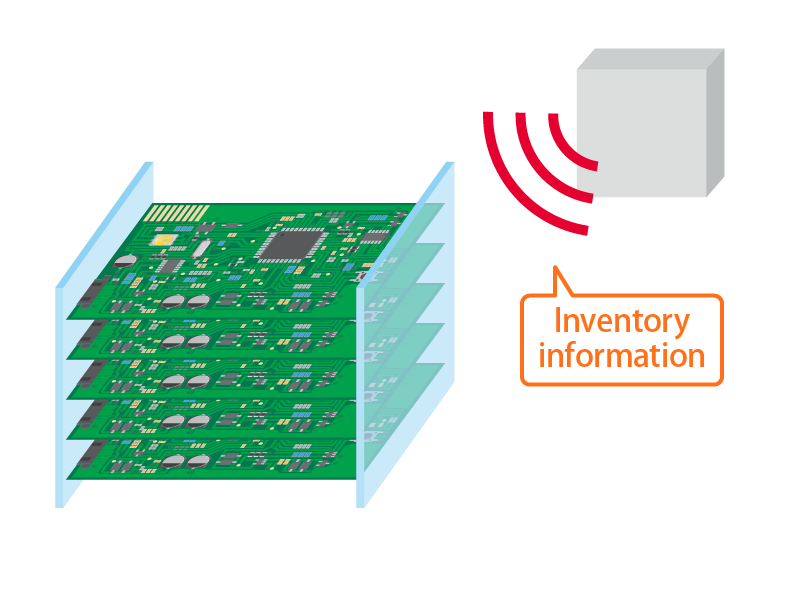

Murata RFID can turn PCB itself into RFID tag, which can help seamless reading in each process. It is also readable as a batch for inventory count.

* The pocket type reader shown in this page, Blueberry UHF MS4 is the product from Tertium Technology.

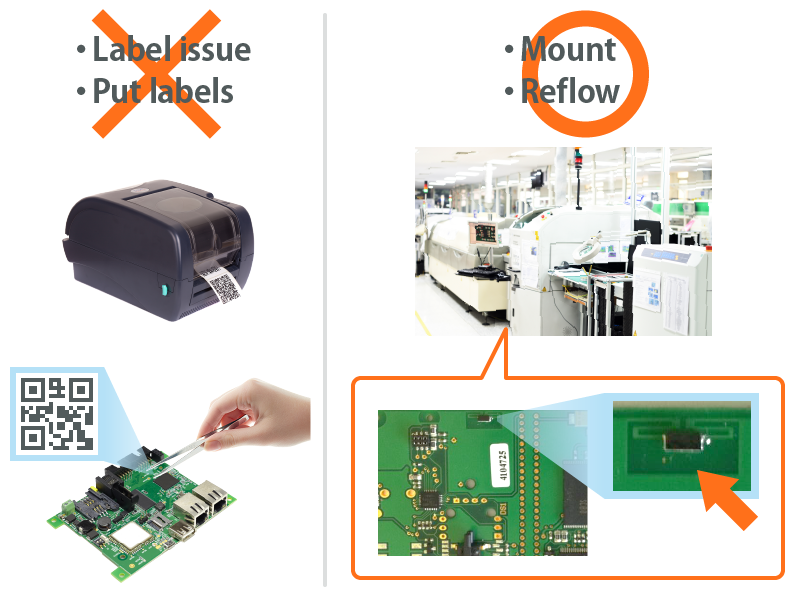

Difficulties in managing PCB with Barcode or QR code Label

-

- Necessary to print and apply labels.

- Large label area is required, which prevents the downsizing of PCB.

-

- 1by1 reading is required.

- The camera position and angle needs to be adjusted for each model.

-

- Another label is needed on the resin cover/casing since the label on the PCB inside is not readable.

- Label outside is vulnerable to dirt and scratches.

Advantages with RFID deployment

-

- RFID chips can be mounted and go through reflow together with other parts.

- Eliminates the time and process for printing and placing the labels.

- Downsizing of PCB is possible since RFID tag requires only a small area.

-

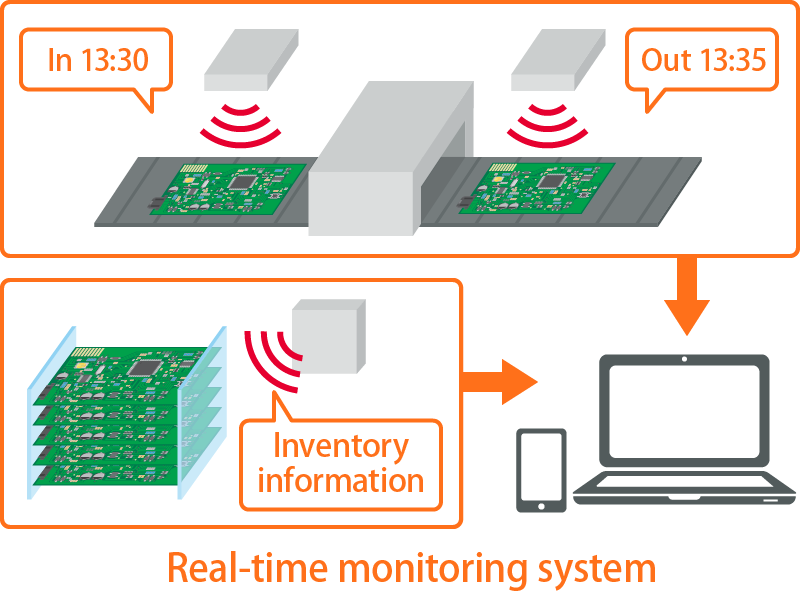

- Real-time monitoring system enables “Smart Factory”, improving process efficiency and optimizing inventory.

-

- It can be read even with the resin cover or the casing in place, and it is possible to get individual information without turning it on. It is also possible to improve operational efficiency, and customer service.

Why RFID

- Readable from the outside even when resin cover or casing is in place.

- Long read range

- Write/rewrite necessary information

Why Murata

- Can be mounted together with other parts before reflow process without printing or placing labels.

- In addition to RFID technology, Murata can also support the implementation of RFID to manufacturing processes based on our experience as a manufacturer.

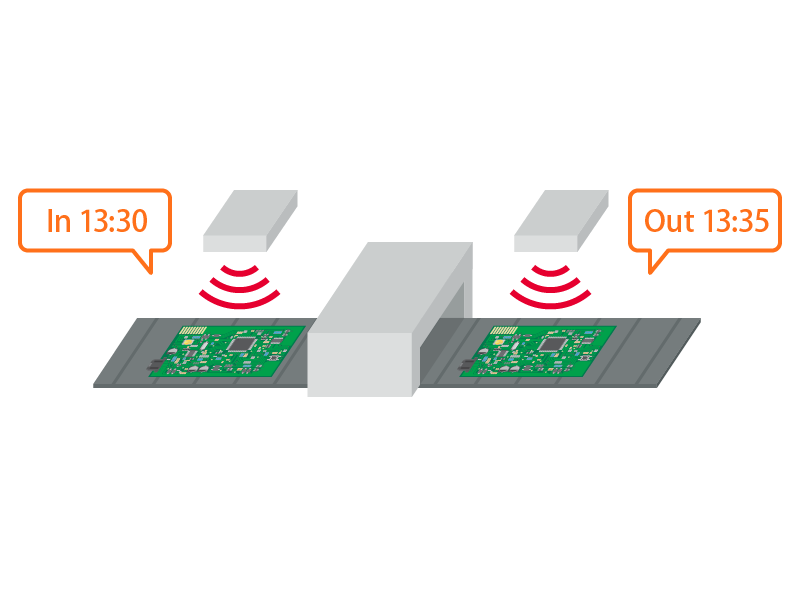

Reading Method

-

- Set antennas before and after the process to register the In/Out information with the server.

-

- Set an antenna in the in-process inventory area and register inventory information in the server.

-

- By using a small portable reader writer, individual information can be obtained from outside the case even at the store/customer center when returning or shipping.

How to attach

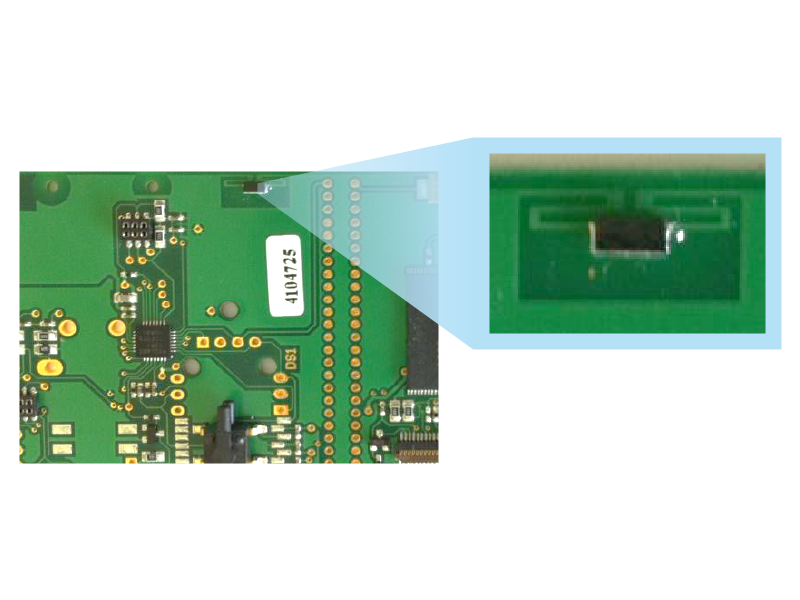

- Print the recommended antenna pattern on your board and mount the RFID Chip.

Read range (Reference)

- ~5m

* Read range is subject to change upon the evaluated environment. We offer suggestions and support based on your usage.

For customers looking for RFID tag/reader-writer.

Murata also offers hardwares from the lineup of RFID tag and reader-writer. Please find the detail in the product page.