Authentification of medical cartridge

with RFID

With RFID technology Murata supports safety in medical care.

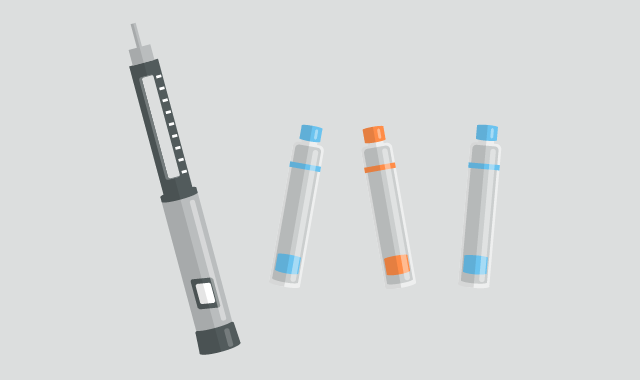

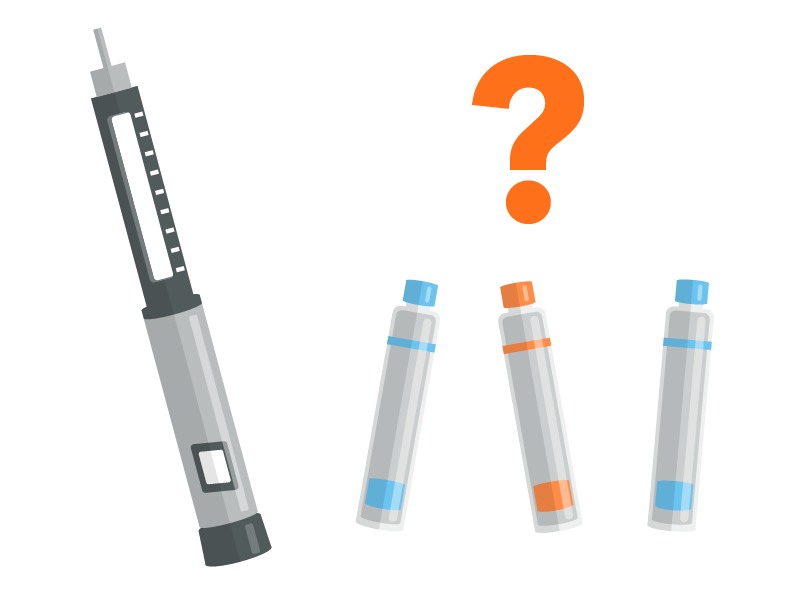

Authentification of drug ampule can prevent medication error and also enable antomatic recording of medication doses.

Difficulties in the medical device market

-

- Failure or error in checking the times of use and expiration date.

-

- It contributes to the reduction of manpower at the medical scenes.

-

- Verification by barcode on the package cannot guarantee the information of the product without package.

Advantages of RFID Deployment

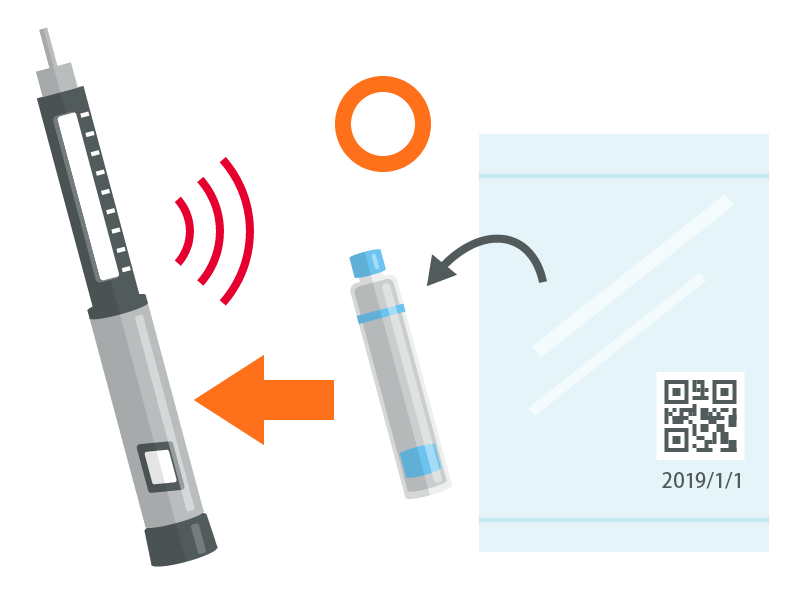

Users can automatically verify that the correct part is used within specified use time and expiration date.

-

- Prevent the use beyond the expiry date and specified use time.

-

- Prevent the use of unwarranted parts

-

- Even after taken out from the package, consumable parts can be identified.

Other value with RFID

-

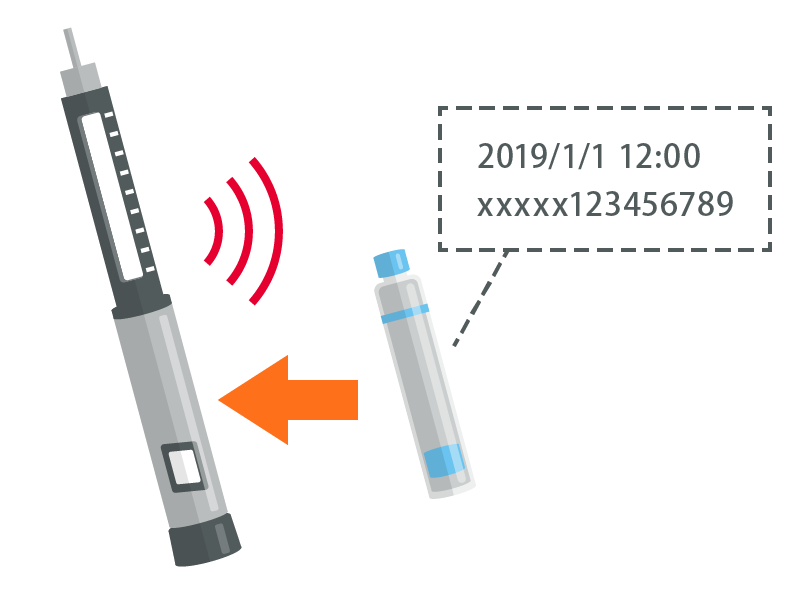

- Encode device setting/prescription history inside memory for each drug ampule.

Why RFID

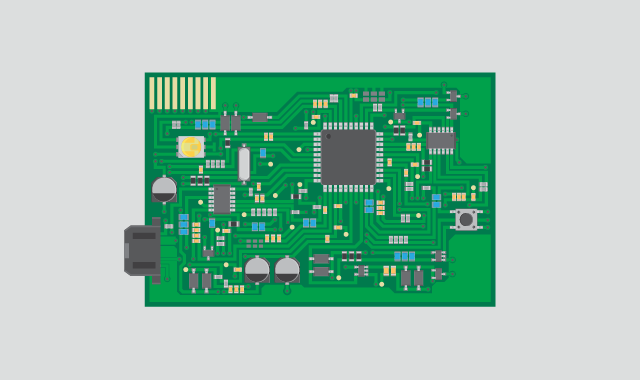

- Store product information and usage history in rewritable memory (User memory, EPC memory). Password lock function prevents memory falsification.

- Each IC has unique, non-rewritable serial number, which can be used to verify product information.

- Near-field communication eliminates the space between reader writer and tag.

- Non-contact reading can avoid the risk of wear out. reader writer and tag can communicate even when contaminated with chemicals, etc.

Why Murata

-

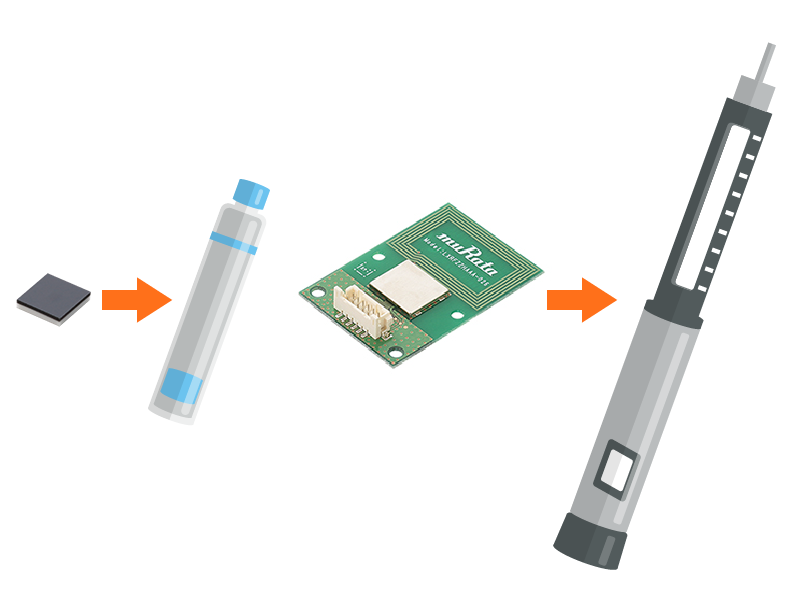

- Small and robust design which can be embedded into products, maintaining current product design.

-

- Near-field communication prevents accidental reading of surrounding parts.

-

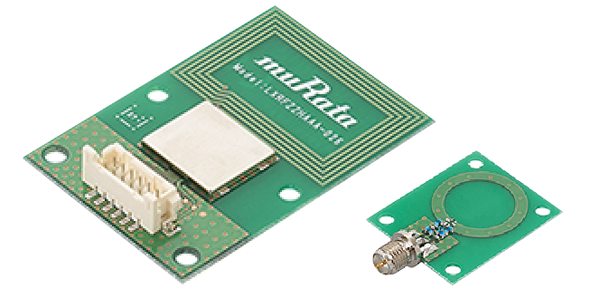

- Murata can support not only tags but also reader writer integration and antenna design.

Reading Method

-

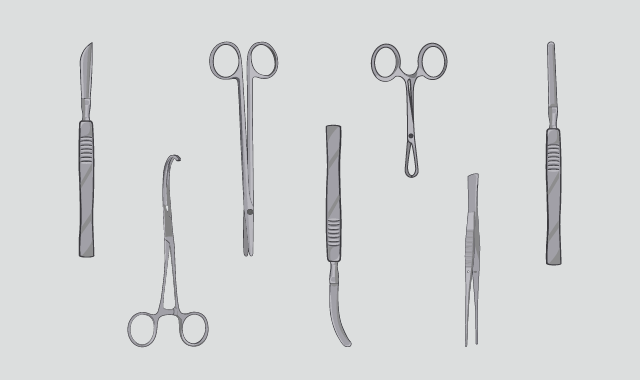

- RFID tags azre incorporated into consumable parts and reader/writer/antenna.

-

- Read and write operations are performed by attaching consumables to the main unit.

How to install

- Adhesive

- Double sided tape

- Injection molding, etc

Read range (Reference)

- Read near neighbor (~20mm*)

* Read range is subject to change upon the evaluated environment. We offer suggestions and support based on your usage.

For customers looking for RFID tag/reader-writer.

Murata also offers hardwares from the lineup of RFID tag and reader-writer. Please find the detail in the product page.