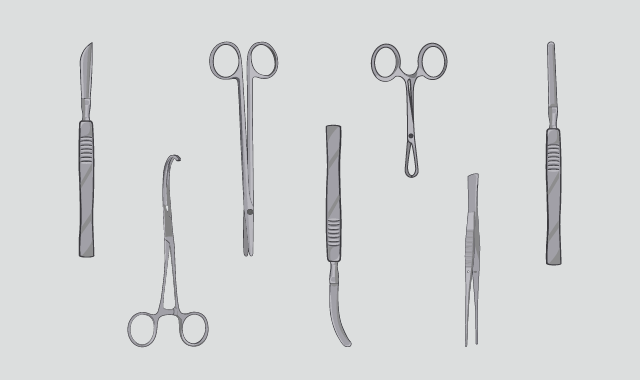

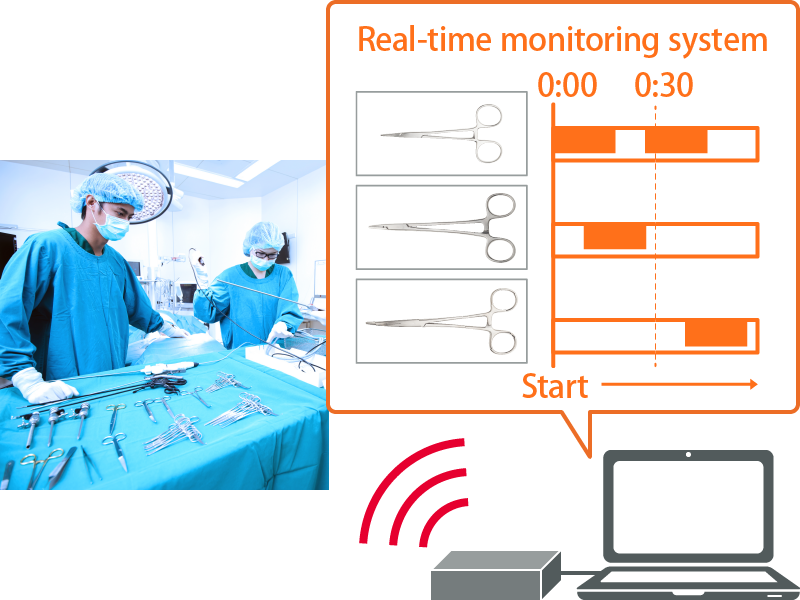

Surgical tool tracking with RFID

With RFID technology Murata supports

the improvement of safety and efficiency during surgery.

US regulations require a UDI (Unique Device Identifier)* be placed on each surgical tool by 2020. Europe follows this movement and plans to complete by 2027.

Additionally, the set up of surgical tools is time consuming even by highly skilled and experienced operators. How to make the process more efficient is a big challenge.

* UDI(Unique Device Identification) regulation

The rule of a product identification that should be applied to all medical devices for the safe use and storage.

Difficulties in surgical tool market

-

- Worldwide trend to make it compulsory to put ID on each surgical tool.

-

- Cannot accurately manage use time due to the difficulty with using manual records.

Assembling and checking the set of tools takes time and manpower.

- Cannot accurately manage use time due to the difficulty with using manual records.

-

- Laser marking is vulnerable to rust and stain.

- 1by1 reading of ID from QR code is time consuming.

Advantages of RFID

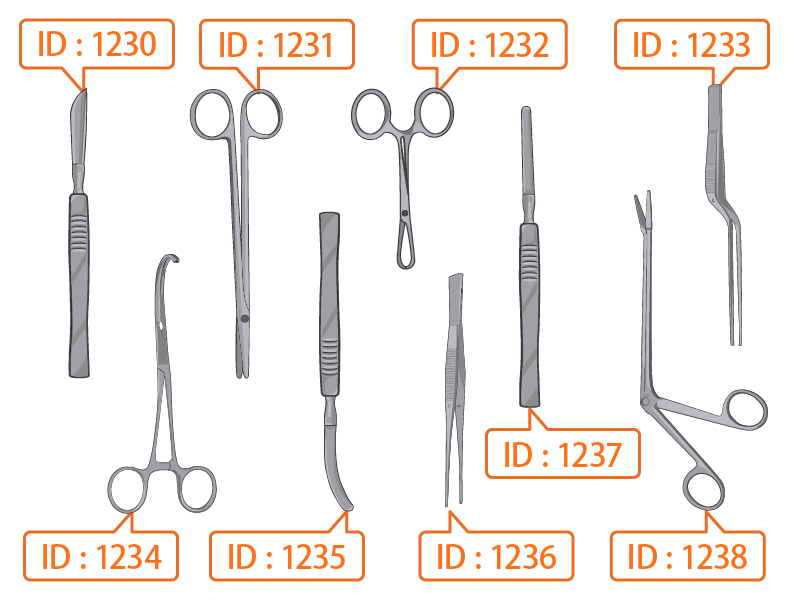

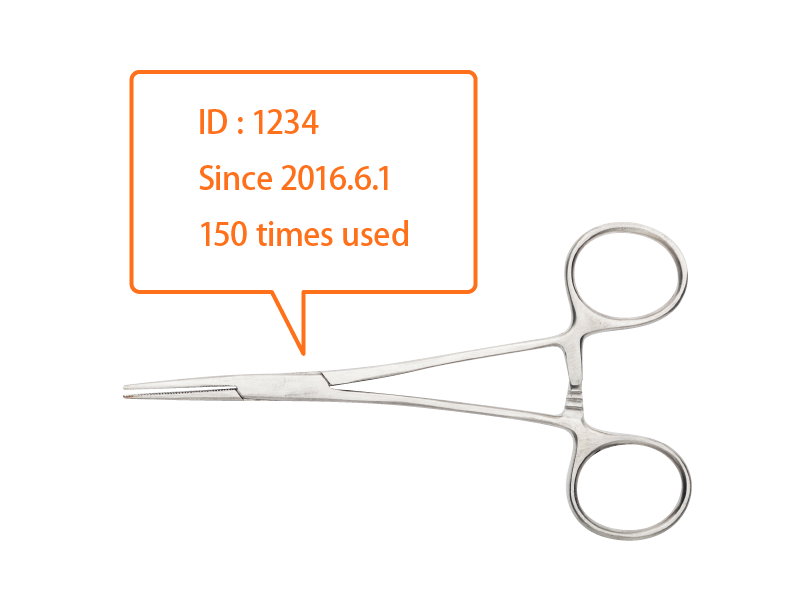

- RFID tag as unique ID.

- Record of use time and life time, makes management easier.

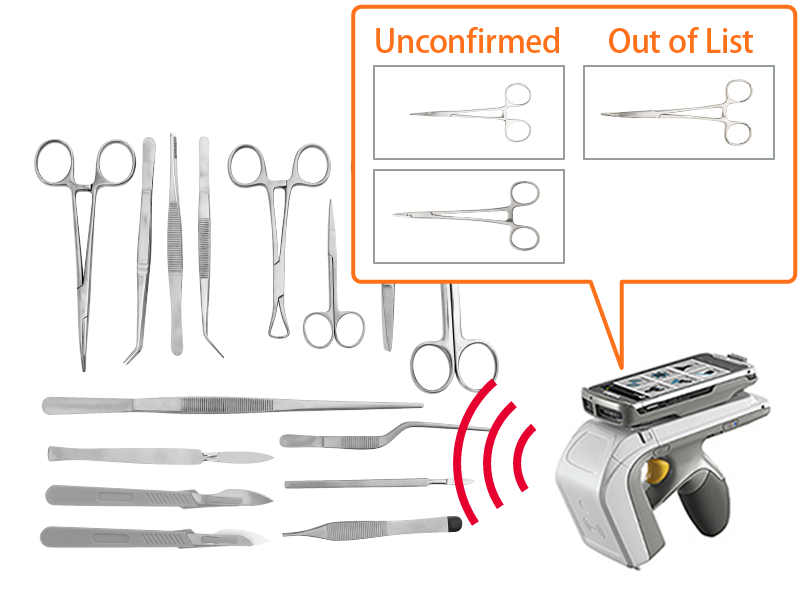

- Quick and batch reading with RFID enables operators to efficiently assemble and check the set of tools.

* RFID Reader in above image.Zebra Technologies RFD8500

- Measuring the times of use for each tool to reduce excessive amount of stock.

- Recording the order of the use to optimize the preparation of tools before surgery.

Why RFID

- Efficient Inventory count and time usage management.

- Reading in batches for quick management.

- Reading is possible even when covered with blood after surgery.

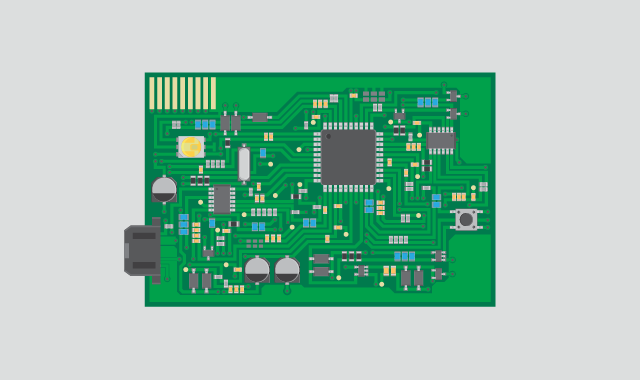

Why Murata

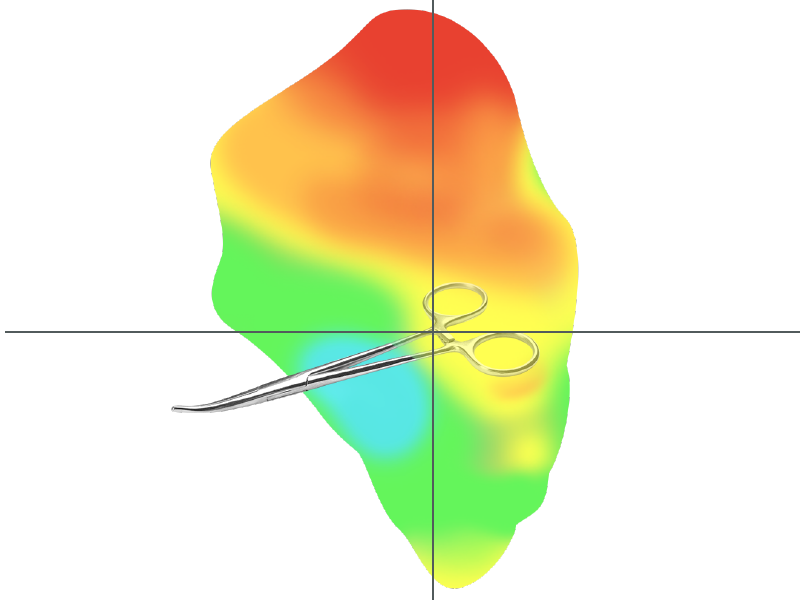

- RFID tag for on-metal application is available.

- Robust RFID tag that can survive auto-clave process is available.

- Murata can offer support on the reading environment and how/where to attach the tag with in-depth knowledge on RF technology.

Reading method

-

- Scanning with hand-held reader writer.

-

- Set reader writer and antennas to read tags without manual operation.

Read range (Reference)

- 10cm~1m

* Read range is subject to change upon the evaluated environment.

Demonstration videos

For customers looking for RFID tag/reader-writer.

Murata also offers hardwares from the lineup of RFID tag and reader-writer. Please find the detail in the product page.