Authentification of medical device

with RFID

With RFID technology Murata supports efficiency and safety in medical care.

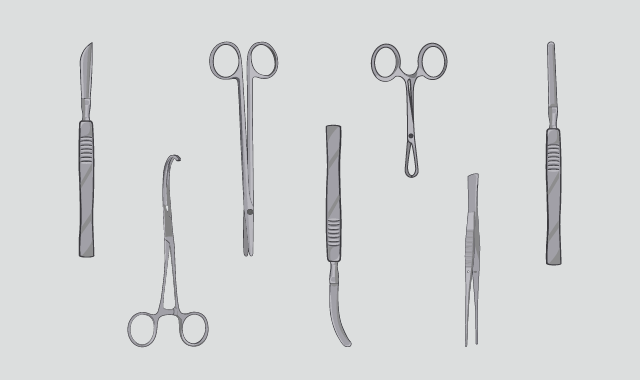

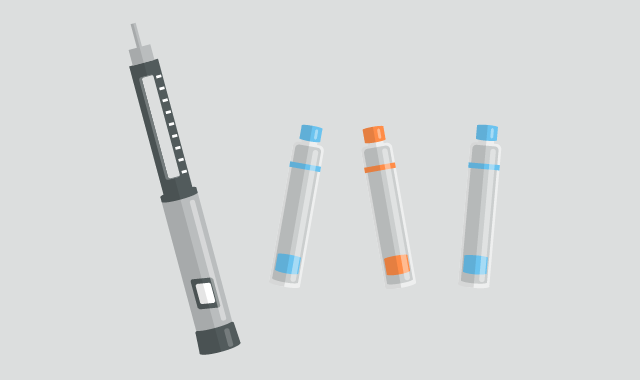

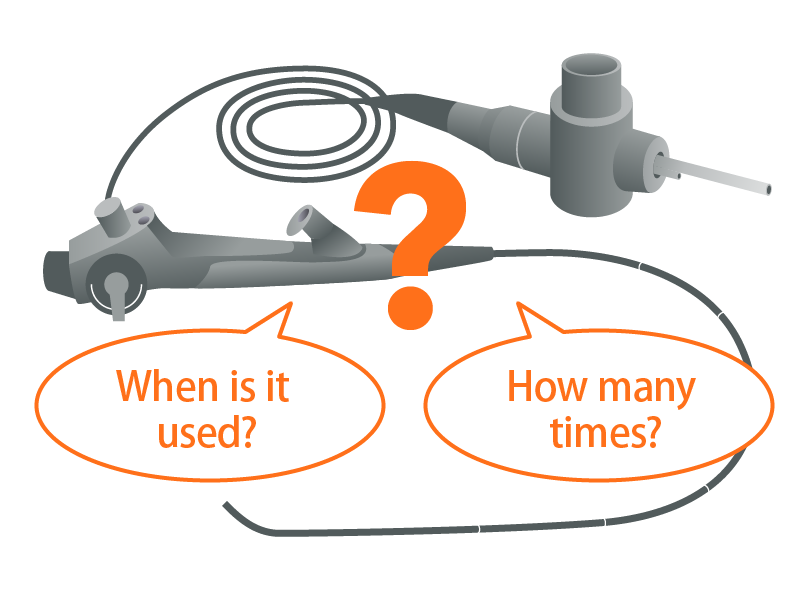

RFID contributes to the proper tracking of usage records of operations or cleanings and for the replacing replacement parts of medical equipment such as endoscopes, ultrasonic diagnostic, scalpels, ultrasonic coagulation and cutting devices.

Additionally, with RFID information automatically recorded and stored, this enables more efficient operation.

Difficulties in the medical device market

medical diagnosis devices such as endoscope requires to keep record of usage to prevent infections.

Additionally, operators need to make sure that the right attachment is connected to right device.

This is currently done with manual identification using Barcodes, which consumes time and manpower.

-

- Possibility of human error such as missing records, losing count of use, not checking expiration date.

-

- Manual operation of Barcode reading.

-

- No information of the usage of medical devices.

Advantages of RFID Deployment

RFID enables automatic records of use for more efficient operation

and prevent the use beyond specified time and period.

- Quick and efficient process to check and record use and expiration date.

- Automatic authentification prevents human error in recording and also improves efficiency.

- Based on the data generated the operating time of the devices and laboratory can be calculated.

- Additionally...

By encoding optimal device settings in each device/attachment, device setting can be automatically verified when the attachment and device are connected.

Why RFID

- Store product information and usage history in rewritable memory (User memory, EPC memory). Password lock function prevents memory falsification.

- Each IC has unique, non-rewritable serial number, which can be used to verify product information.

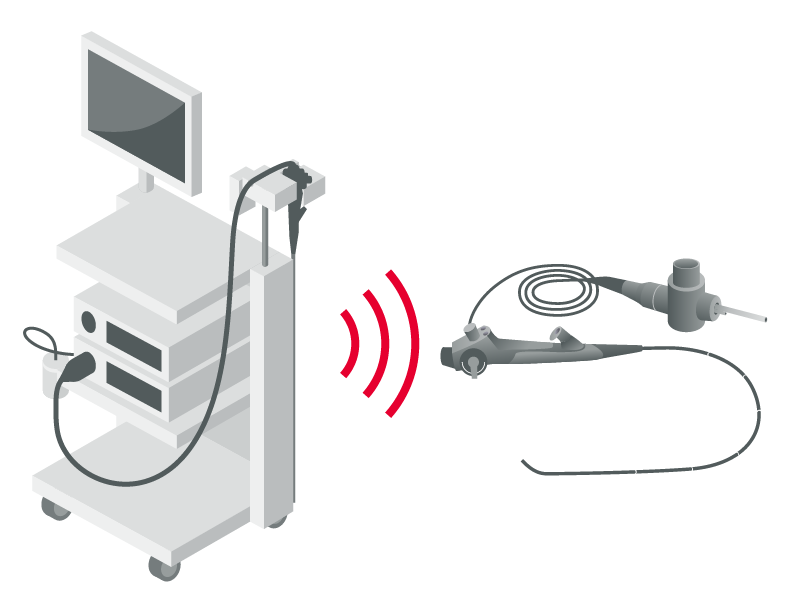

- Near-field communication eliminates the space between reader writer and tag.

- Non-contact reading can avoid the risk of wear out. reader writer and tag can communicate even when contaminated with chemicals, etc.

Why Murata

-

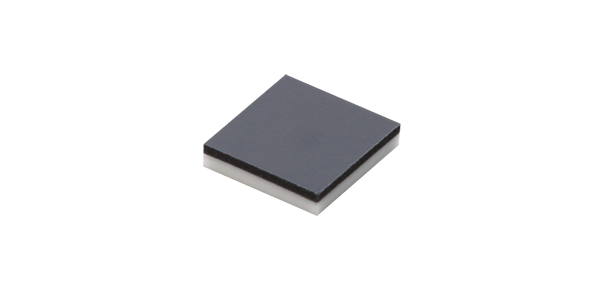

- Small and robust which can be embedded into products, maintaining current product design.

-

- Near-field communication prevents accidental reading of surrounding parts.

-

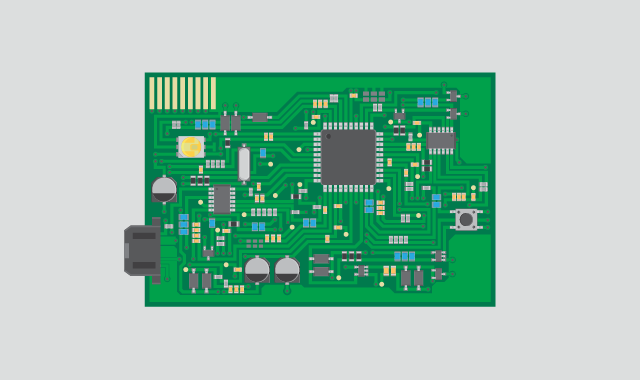

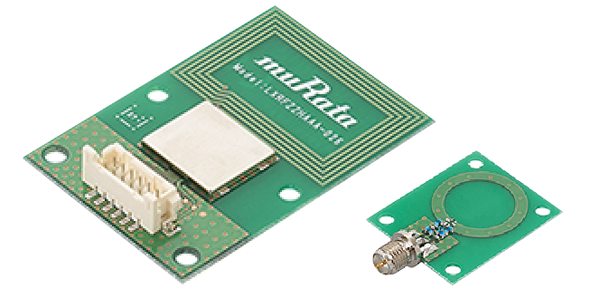

- Murata can support not only tags but also reader writer integration and antenna design.

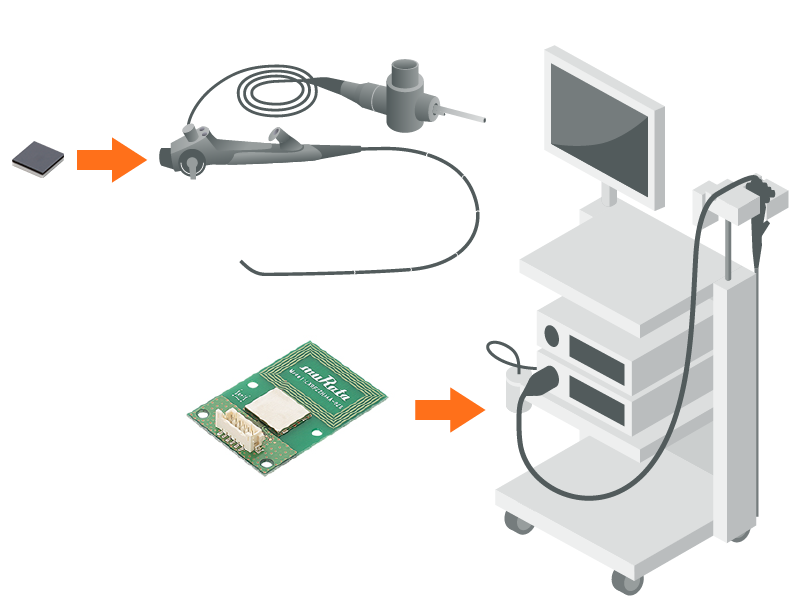

Reading Method

-

- RFID tags azre incorporated into Endoscope and reader/writer/antenna.

-

- Read and write operations are performed by attaching consumables to the Endoscope systems.

How to attach

- Adhesive

- Double sided tape

- Injection molding, etc.

Read range (Reference)

- Read near neighbor (~20mm *)

* Read range is subject to change upon the evaluated environment. We offer suggestions and support based on your usage.

For customers looking for RFID tag/reader-writer.

Murata also offers hardwares from the lineup of RFID tag and reader-writer. Please find the detail in the product page.