Traceability for small products with RFID

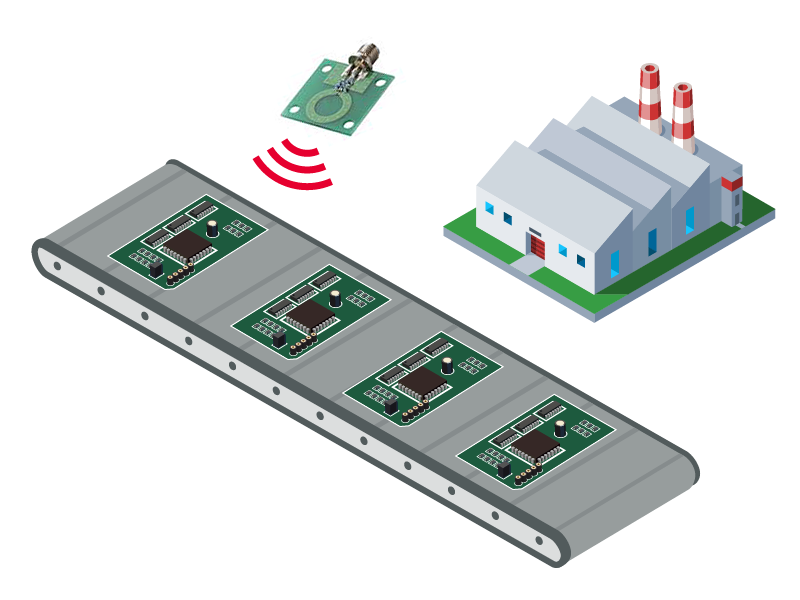

With RFID technology Murata supports improvement of efficiency

in the production process and customer support.

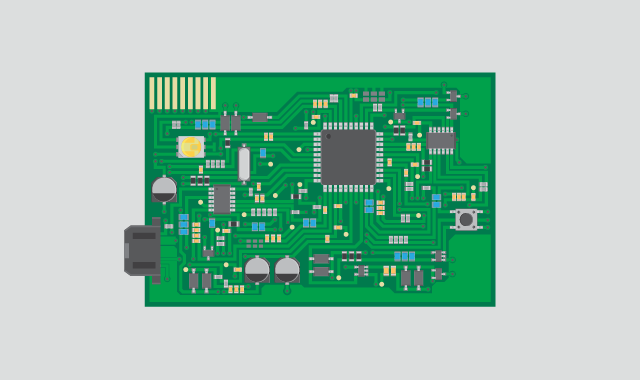

Products that requires individual setting, such as hearing aid, needs product information recorded in each product. Using conventional methods such as QR code is becoming difficult due to the downsizing of products.

Additionally, hearing aids are usually in direct contact with the skin, and labels attached on products can get dirty. This might prevent the smooth identification of products.

* The pocket type reader shown in this page, Blueberry UHF MS4 is the product from Tertium Technology.

Difficulties in the hearing aid market

Manufacturing record and individual device configurations are managed through separate means.

Please flick and have a look.![[Factory] With the downsizing of the board, the QR code cannot be traced in units of slave boards. Adjustment of individual device configurations are required. [Store / customer service] After a product is returned , its individual configuration is difficult to access during recalibration. Used products are difficult to identify because the identification label is dirty. [Customer] Ensure that any product with custom configuration is delivered to its intended destination.](/en-global/service/rfid-solution/asset/solution/img/img_ex_hearing-aid03.png)

Advantages of RFID

Centralized management from the manufacturing stage to the after-market is possible.

Please flick and have a look.![[Factory] Linking with board information, managing history in manufacturing process, and linking with amplifier values. [Logistics Center] Final confirmation that the shipping destination and amplifier adjustment data are correct. [Store / customer service] Identification of returned products from outside the case. Amplifier information can be confirmed. Efficient identification of returned items.](/en-global/service/rfid-solution/asset/solution/img/img_ex_hearing-aid04.png)

Why RFID

- Can be read from the outside even when placed inside the product.

- rewritable

- resistant to dirt

Why Murata

-

- Small and robust. Possible to mount on substrates and to resin-mold.

By taking advantage of the above features, history can be tracked from the beginning of the manufacturing process.

- Small and robust. Possible to mount on substrates and to resin-mold.

-

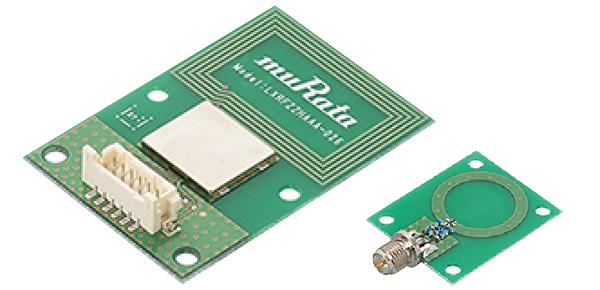

- Murata can support reader writer integration and antenna design as well as RFID tags.

Reading Method

-

- Dedicated loop antenna for small tag is set in each point at production process.

-

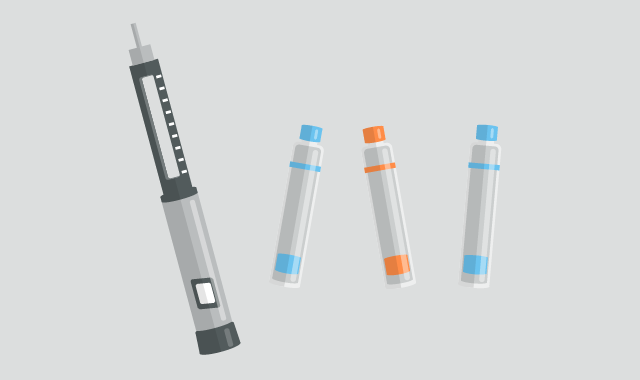

- Small portable reader writer devices allows you to check product information and settings even at the store/customer center when returned or before shipping.

How to attach

- Adhesive

- Double sided tape

- Injection molding, etc.

Read range (Reference)

- Reading in near field (Contact ~ 20mm)*

* Read range is subject to change upon the evaluated environment. We offer suggestions and support based on your usage.

For customers looking for RFID tag/reader-writer.

Murata also offers hardwares from the lineup of RFID tag and reader-writer. Please find the detail in the product page.