RFID by Industry

At Murata ID Solutions, we have worked with and support a huge range of Industry sectors, including fashion, healthcare, retail, pharmaceutical, industrial, manufacturing and logistics.

Fashion & Apparel

The fashion industry is driving the development of RFID. Deployments in fashion and apparel companies have reached the early majority stage and the industry applies RFID to cover 18 different use cases. Results show that RFID is valuable not only for cost reduction but also for turnover increase. Fashion deploys RFID to improve processes at store level but also to optimize the logistics and manufacturing processes.

Thanks to the partnership with RFID lab of the University of Parma, we closely monitor the development of the use cases in fashion and apparel and engineer our RFID systems to respond to the industry’s latest needs and requirements.

Benefits of RFID

Murata RFID for Fashion & Apparel

Murata ID Solutions has followed rollouts of leading retailers worldwide automatizing both store and supply chain processes. An important player uses our RFID solutions to control the grey market across the world, from China to Brazil. Another maps out the floor performances and boosts sales at all its stores thanks to our RFID system.

With distinctive competences in operations and supply chain management, we have engineered RFID solutions that optimize the logistics and manufacturing processes.

At store level, our systems are engineered to track all product flows in the store with RFID in order to obtain accurate and real-time data (not only data relative to the latest inventory count). We have pushed the visibility to the highest level in order to apply RFID not only for inventory counts but also for replenishment from the backroom and for visual merchandising.

Thanks to the experience gained, our packaged software solution id-Bridge Retail is already customized, ready to implement and easy to integrate with all legacy systems.

FMCG & Food

Food and FMCG were among the first industries to recognize the benefits of RFID. Today there is a growing interest in RFID for the logistics processes but also for usage at the Point of Sale applying RFID at item level. Japan aims to automate all convenience stores by 2025 tagging every product with RFID. Other retailers are deploying RFID at item level to automate checkout in convenience stores and supermarkets.

When applied at item level, RFID guarantees accurate and real-time traceability of the single product throughout the whole supply chain. It allows the single store to automate its processes and implement self-checkout based on RFID.

By tagging pallets and shipment units, RFID enables the distribution centers to optimize inbound and outbound flows cutting receiving time and reducing errors and shrinkage.

Benefits of RFID

Murata RFID for FMCG & Food

Murata ID Solutions enables important players in the FMCG industry to track shipping units with RFID, optimizing the inbound/outbound processes at their distribution centers and cutting receiving time by 50%. Our RFID solutions furthermore enables FEFO (first expired, first out) shelf-life management.

Thanks to real-time information and alerts, RFID makes it possible to automatically monitor the temperature at all stages of the supply chain. Leading 3PL companies use our RFID solutions for cold chain management. In collaboration with the RFID Lab of the University of Parma, we have developed a very sophisticated BI dashboard with alarms in case of breaking of the cold chain.

Our “Genuine” app, a specific authentication app, leverages RFID data to effectively control and fight back in grey markets. It also enables the consumer to verify the authenticity of the products by themselves.

Healthcare & Pharmaceutical

RFID helps hospitals and pharmaceutical companies to improve services, cut costs, increase sales and eliminate healthcare risks.

The technology offers a simple-to-use and efficient system for tracking and managing assets, patients, employees, medical devices, pharmaceutical products, and much more. It prevents loss, enables quick identification and location, enhance security and maximise efficiency and emergency response. The technology also enables collaborative models such as vendor managed inventory.

In the pharmaceutical industry RFID is particularly useful for end-to-end supply chain visibility and traceability and to combat grey and black market.

Benefits of RFID

Murata RFID for Healthcare & Pharmaceutical

An important pharmaceutical group deploys our RFID solutions for product tracking and for vendor managed inventory and continuous replenishment. Thanks to the visibility generated by RFID, the company can accurately monitor the customer’s stock levels and replenish solely when necessary thus trimming stock levels and costs.

Our RFID solution has also been deployed by a leading pharmaceutical company to gain real-time visibility of their entire supply chain. Thanks to RFID every box of pharmaceutical product is tracked individually throughout the entire supply chain increasing the visibility, the service level, the rate of productivity and the logistics accuracy.

Other pharmaceutical companies deploy our solutions to better manage the cold chain of their products.

Logistics & Transportation

Real-time visibility of goods improves the efficiency of the whole supply-chain. Regardless the industry, tagging every box, pallet or shipping crate with an RFID label enables manifold opportunities in the DC as well as during transportation. Detailed RFID tracking and transparency can help save valuable time and operational costs.

In the DC, RFID enables inbound/outbound flows optimization, inventory accuracy, shelf life management according to FEFO (first-expired, first-out) instead of FIFO (first-in, first-out), packing accuracy and trim shrinkage.

During transportation RFID allows loading/unloading time reduction by 50%, optimized LIFO (last-in, first-out) cargo loading/unloading, shrinkage reduction.

Benefits of RFID

Murata RFID for Logistics & Transportation

With distinctive competences in operations, logistics, and supply chain management our RFID solutions help companies worldwide optimize their distribution and logistics processes.

Our solutions enable leading manufacturers and retailers to gain real-time open supply chain visibility optimizing inventory levels, productivity and logistics accuracy.

Leading 3PL companies use our RFID solutions for cold chain management as well as for asset management avoiding losses, misplacement and inventory differences.

Manufacturing

Industry 4.0 - the 4th industrial revolution - is the automation and digitisation of manufacturing. Thanks to technologies, such as IoT and RFID, objects and machines become intelligent and capable of communicating with each other without human interference.

RFID technology connects components, processes and machines providing automated identification of the objects and real-time information on the entire production cycle. Any irregularities, errors or setbacks in the production can be identified immediately improving the production rate, efficiency and safety.

Information about work in progress of a lot can be real time available and accurate at the single item level.

Benefits of RFID

Murata RFID for Manufacturing

Our RFID solutions are deployed in manufacturing by several companies to optimize the workflow, to track every component and to have real-time visibility of the entire production cycle.

Thanks to RFID the manufacturer can have accurate and real-time information on the production progress and get alerts on the BI dashboard in case of errors or irregularities.

Murata ID Solutions has developed an innovative RFID solution for an important food manufacturer. An RFID-enabled product communicates with an RFID-enabled machine. The machine sets its operations according to the information transferred by the tag on the product and makes cooking automated. The tag also contains important information such as the genuinity and the expiry date of the product.

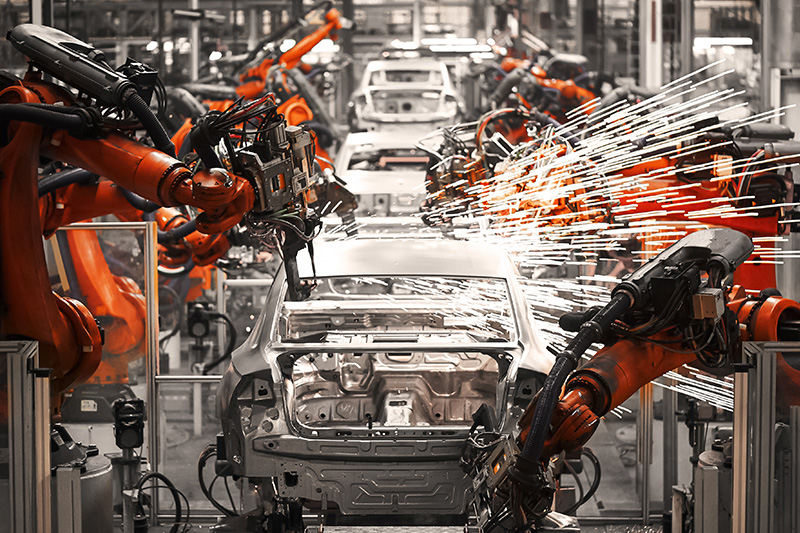

Automotive

The automotive industry is approaching RFID with the same goals as the manufacturing industry. In average more than 15 tags are hidden in a car by suppliers, car manufacturers and distributers.

RFID provides several advantages for the automotive industry, such as automation of the inbound/outbound flows and of the production stages and progress.

Essential for the automotive industry is automation tracking of the single components when they enter the production line and subsequently the ability to link them to the assembled car for traceability purposes. Recalls can be selective and trimmed down only to real needs.

Benefits of RFID

Murata RFID for Automotive

Knowing the exact location of every single component in assembly allows the producer to track and identify, at any time, any damaged or dangerous components. This increases the security level exponentially and radically simplifies the identification and tracking processes.

For exactly these purposes, Murata ID Solutions have engineered an RFID system for a first-tier supplier in the automotive industry. Thanks to RFID, they can be 100% sure that only verified products are shipped downstream and that they qualify for the security levels requested by their customers.