Wireless Sensing SolutionCASE STUDY

Reduced the electrical power costs for air-conditioning equipment by roughly 6 million yen per year! Achieved a reduction in CO2 emissions of 198.8 tons per year.

Visualized the temperature variations within the process to optimize the HVAC control

- Industry type

- Electronic component manufacturer

- Occupation

- Environmental Control Manager

- Implemented product

- Temperature Humidity Sensor Unit

- Target equipment

- Clean room air-conditioning equipment

Issues and results

-

It appeared that unnecessary electricity was being used on air conditioning, but the waste could not be visualizedVisualized temperature variations within the process to optimize the air-conditioning equipment control. As a result, the cost of electrical power for the air-conditioning equipment was reduced by roughly 6 million yen per year, and CO2 emissions were reduced by 198.8 tons per year.

Key implementation points

Low implementation cost and easy to install.

Implementation

Because the sensors can be easily added post-installation in a wireless manner, the customer determined where to install the wireless Temperature Humidity Sensor Unit on their own and collected the temperature information.

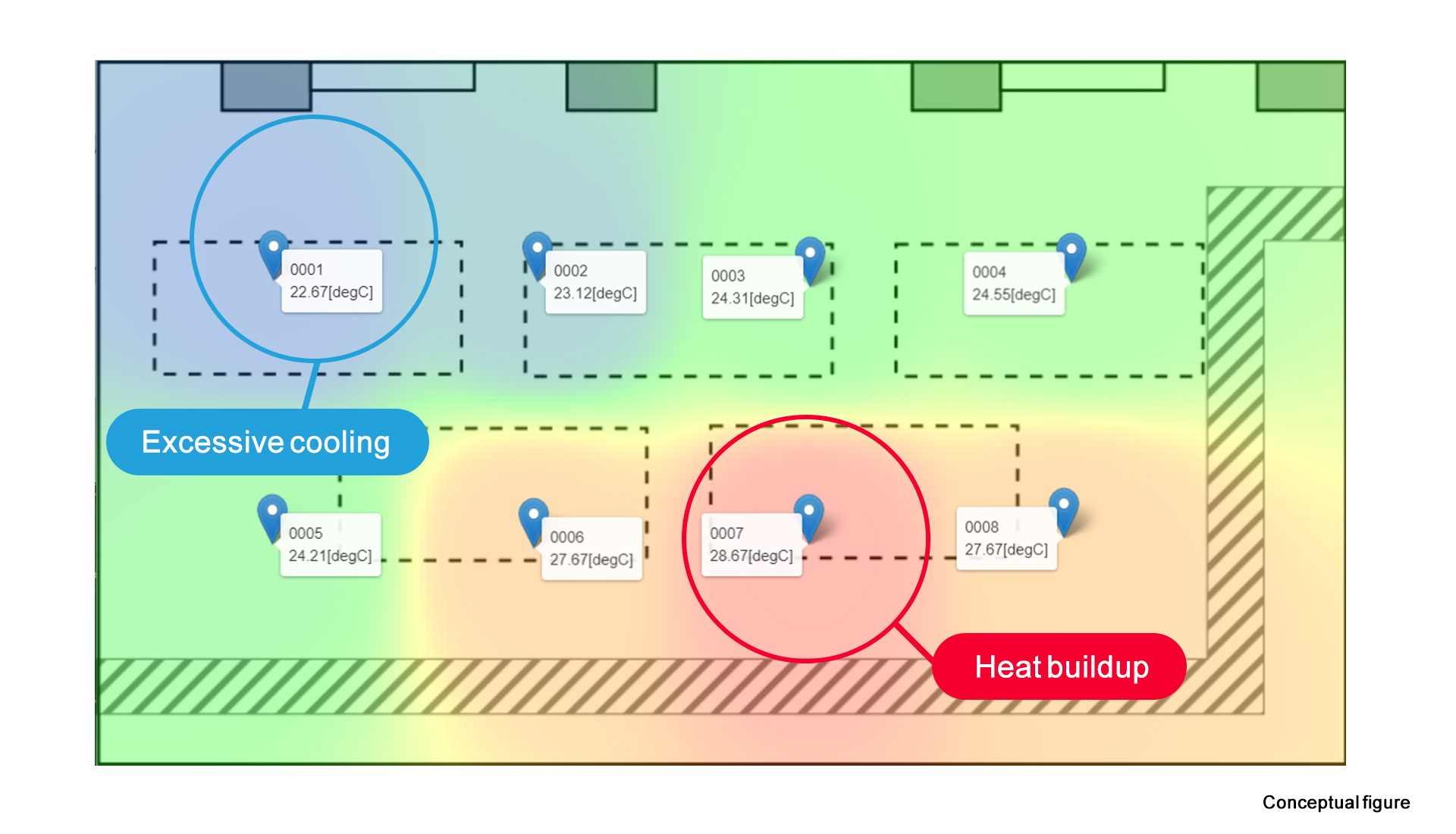

The collected temperature values were displayed as a heat map with an application to visualize the variations in temperature (heat buildup and excessive cooling).

Results

By optimizing the HVAC control to correct the temperature variations,

・CO2 emissions were reduced by 198.8 tons per year

・Cost of electrical power was reduced by roughly 6 million yen per year

Related products

For more details, please inquire on the Contact page.