Wireless Sensing SolutionCASE STUDY

Reduced work in progress disposal loss by several million yen and equipment repair costs by roughly 3 million yen per year!

Resolved problems with mounters on a connected line through predictive maintenance

- Industry type

- Electronic component manufacturer

- Occupation

- Facility Maintenance Manager

- Implemented product

- 4-20mA and Pulse Signal Unit

- Target equipment

- Vacuum pumps

Issues and results

-

Work in progress disposal due to mounter problems・Reduced work in progress disposal losses by several million yen

-

Increase in repair costs and a deterioration in work efficiency due to sudden troubleshooting after problems occurred・Reduced equipment repair costs by roughly 3 million yen per year

・Increased the work efficiency of maintenance staff members

Implementation background

Problems with mounters frequently occurred on a connected line. When even one unit stops, all of the work in progress is ruined.

The majority of the problems occurred due to vacuum pump failures that required sudden troubleshooting.

Implementation

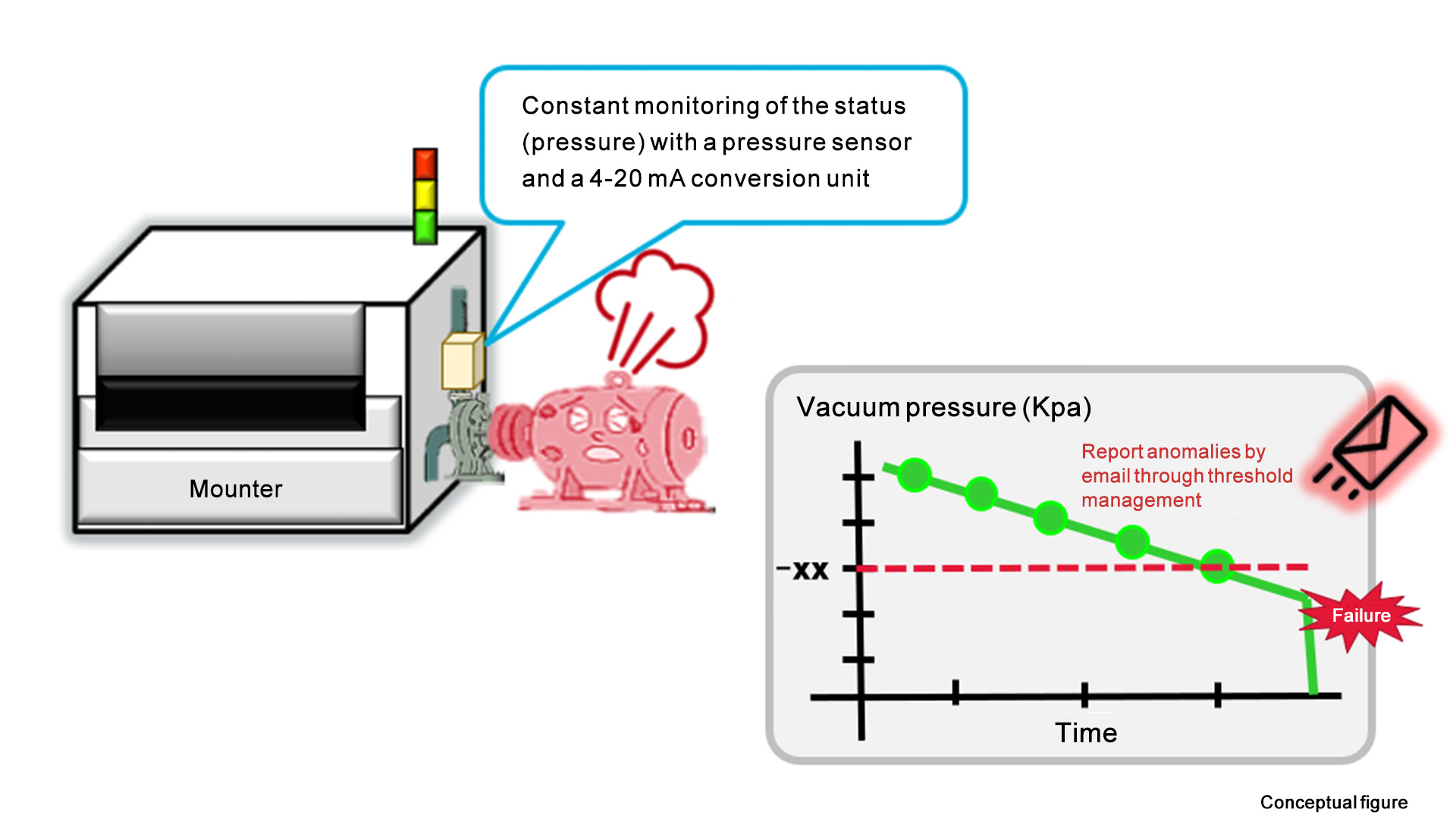

Because the vacuum pressure deteriorates when the vacuum pump fails, the vacuum pressure trends were monitored with a wireless 4-20mA and Pulse Signal Unit.

Anomalies are reported by email to the manager before a failure by managing the vacuum pressure threshold.

Results

Because anomalies are reported by email to the manager before a failure, it enables systematic maintenance before an equipment failure rather than sudden troubleshooting after an equipment failure. This produced the following three results.

・Reduced work in progress disposal loss by several million yen

・Reduced repair costs by roughly 3 million yen per year

・Improved the work efficiency of maintenance staff members

Related products

For more details, please inquire on the Contact page.